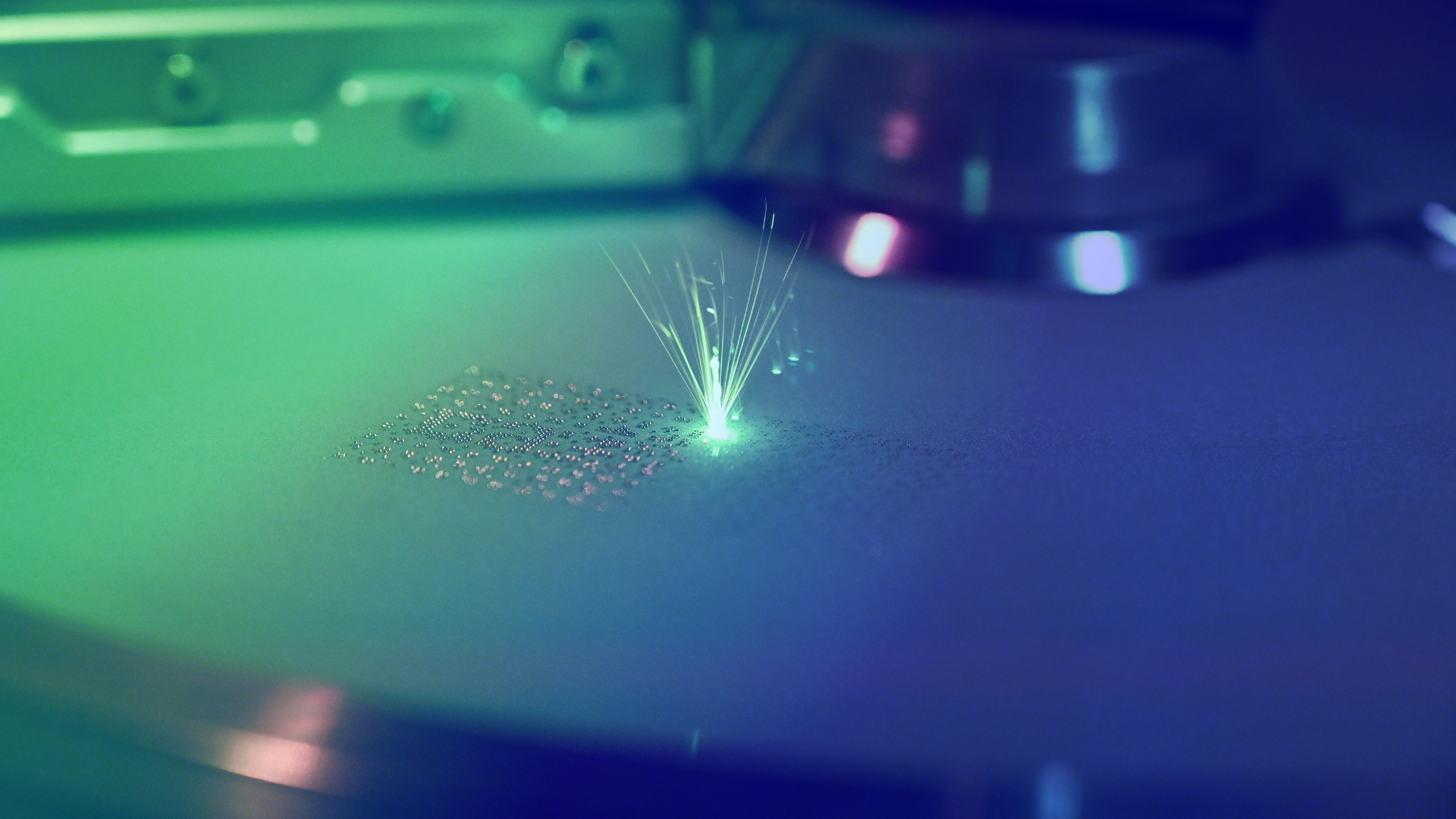

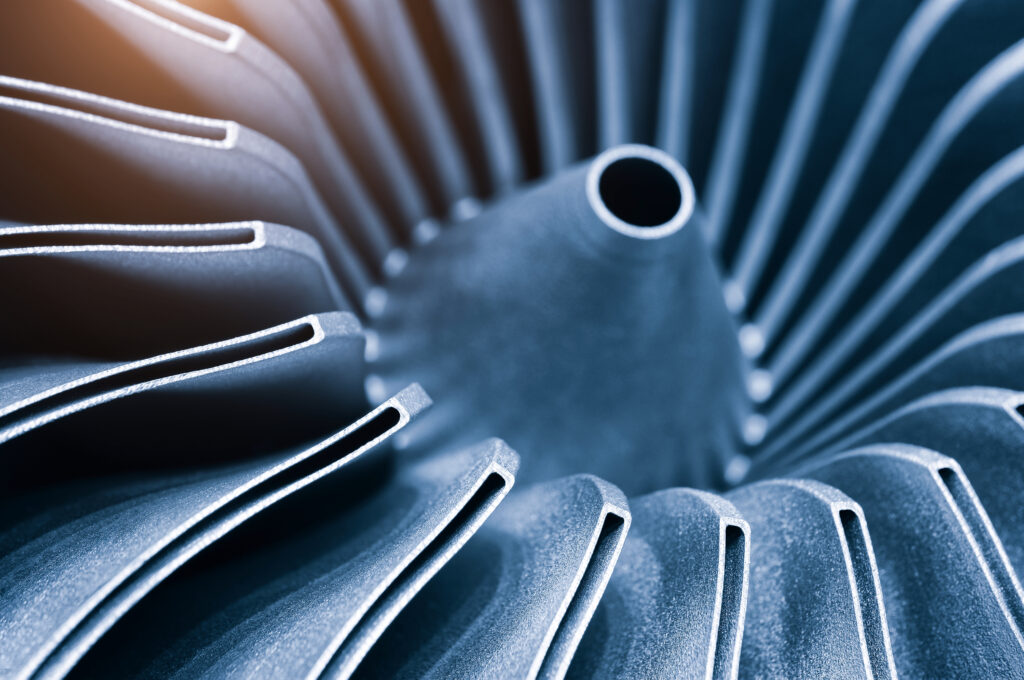

How Direct Metal Laser Sintering Works

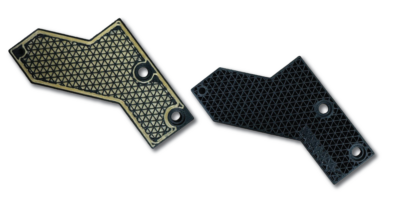

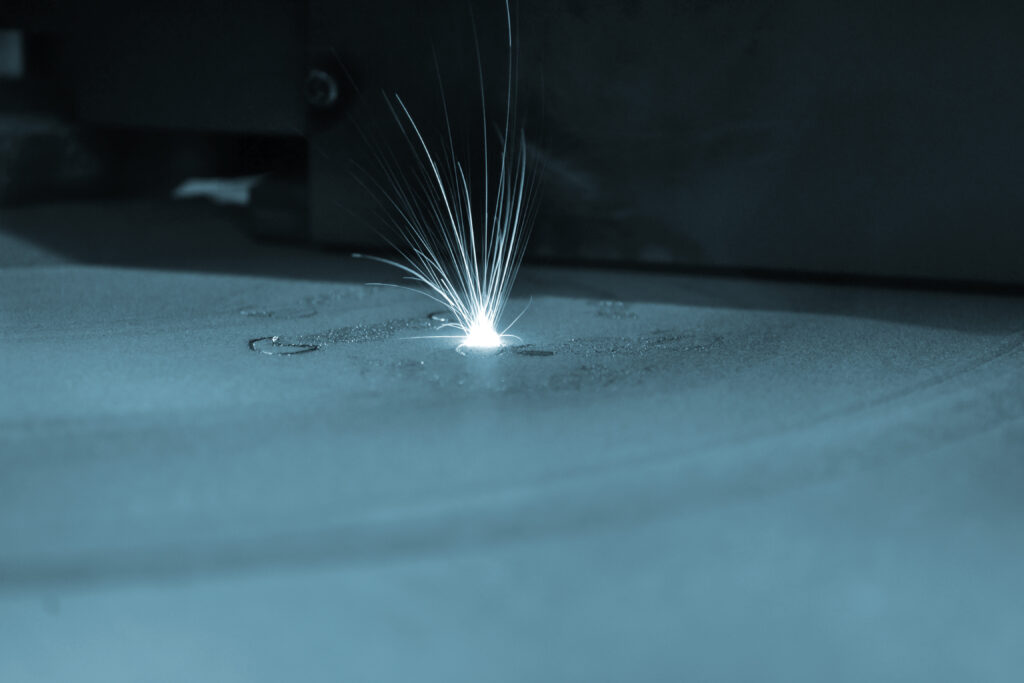

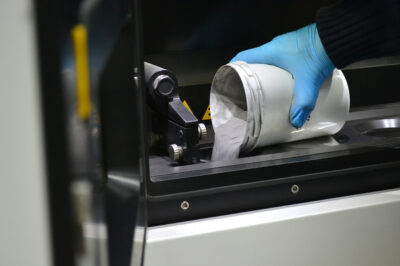

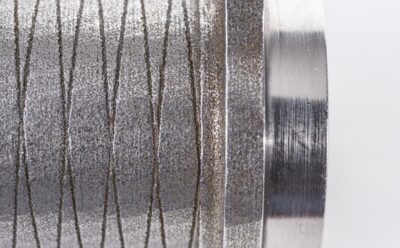

Direct Metal Laser Sintering (DMLS) quickly creates precise metal prototypes or production parts on demand, even with complex geometries. The process melts fine-metal powder, layer by layer, with a laser beam to create a final part with properties comparable to traditionally manufactured metal parts. Your DMLS parts can be produced using a variety of prototype and production metal materials, including stainless steel, maraging steel, aluminum, titanium, and more.

Here’s how our DMLS additive solutions can help you:

- Produce fully-dense metal parts with the same manufacturing versatility as non-metal 3D printed parts.

- Remove the need for polymer binders, burn-off and infiltration steps, and heavy upfront tooling.

- Prototype in various production-grade metals and alloys (aluminum, titanium, stainless steel, cobalt chrome, etc.)

- Accelerate metal manufacturing of parts built directly from 3D CAD data.

Our Direct Metal Laser Sintering Capabilities

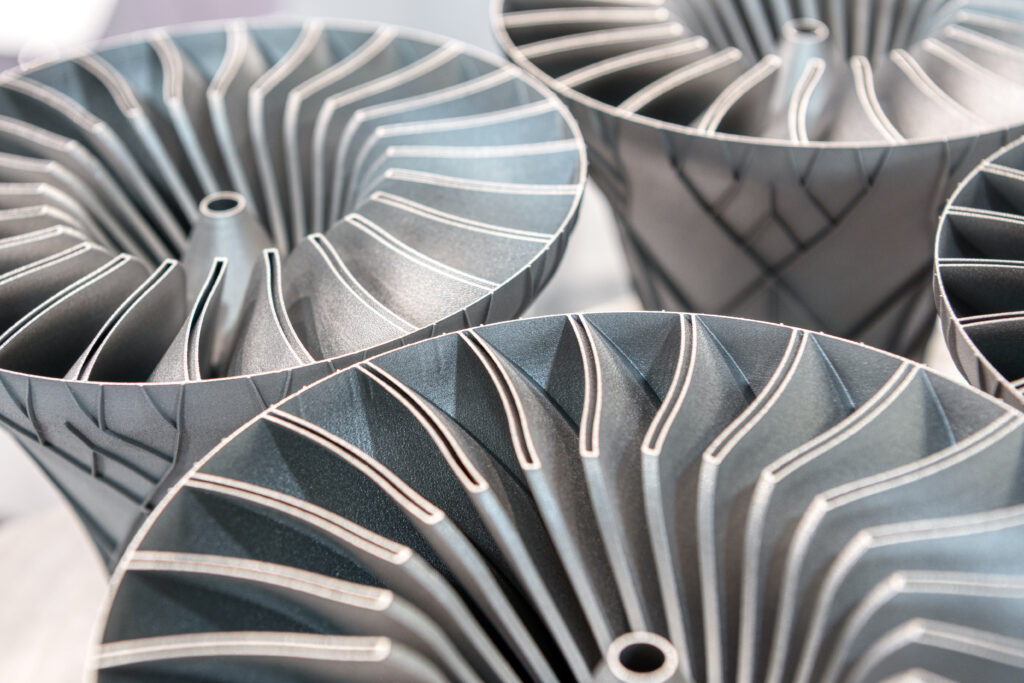

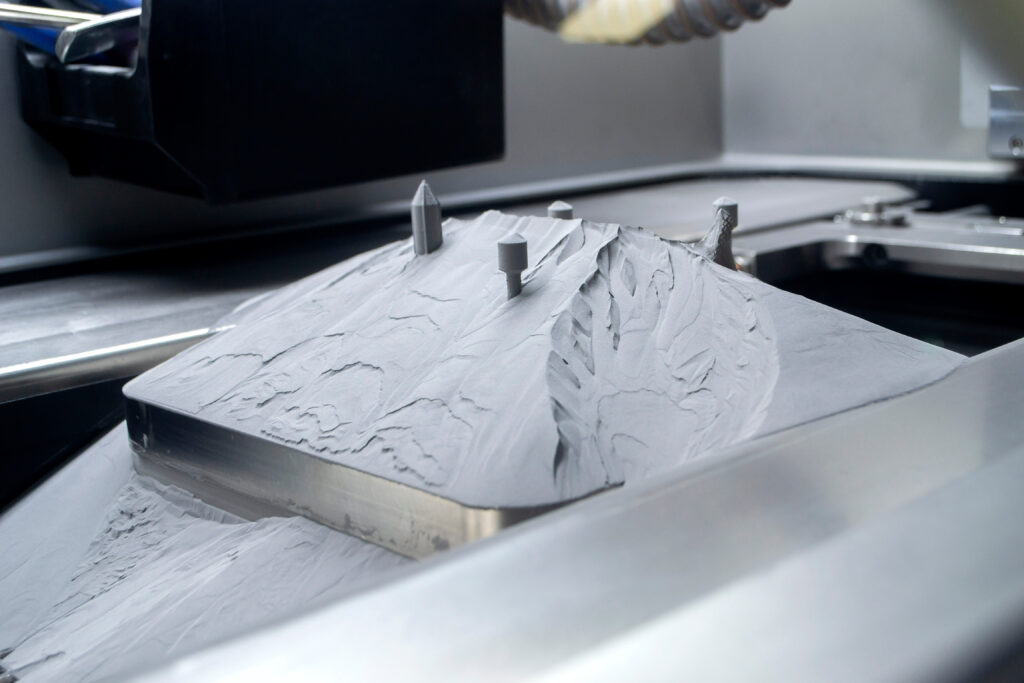

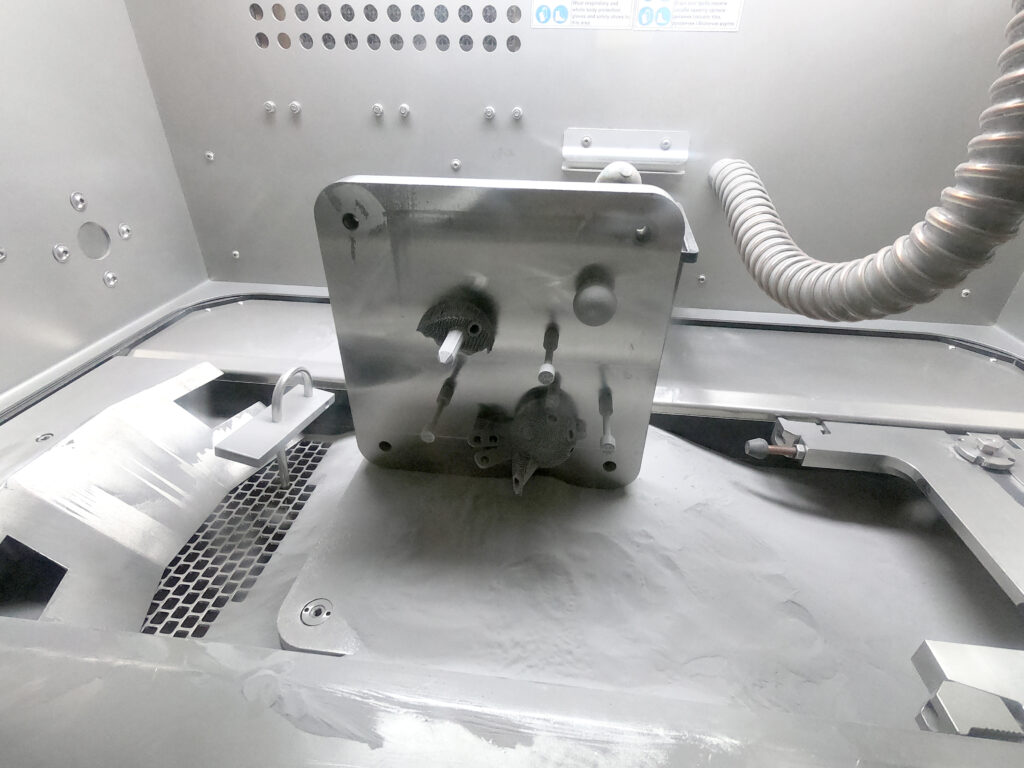

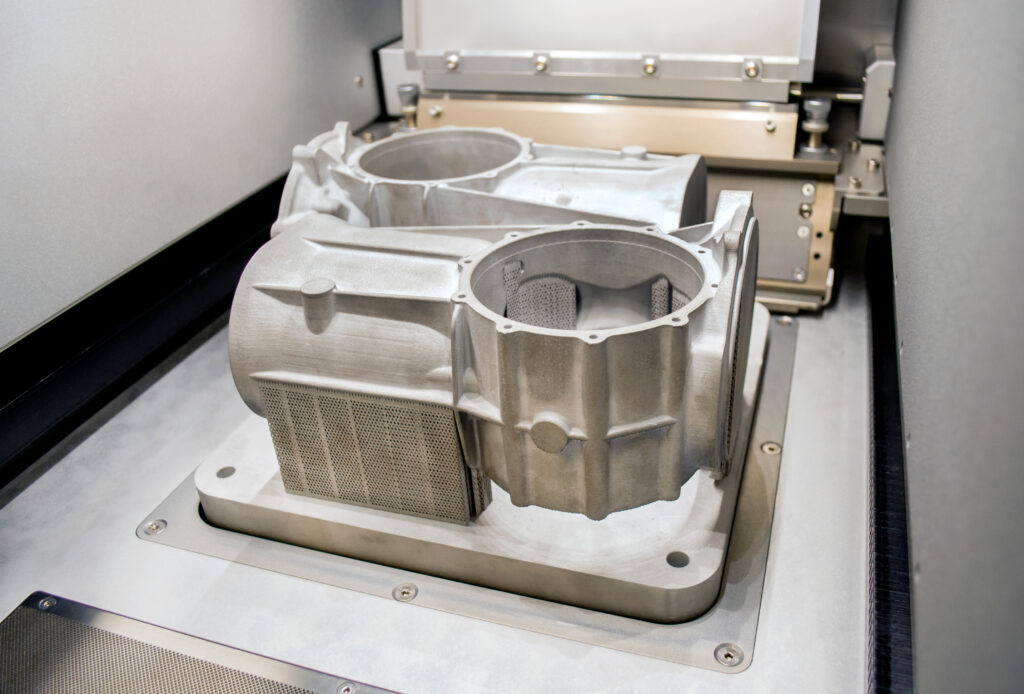

When you need quick-turn metal parts, UPTIVE DMLS solutions offer increased speed and versatility, even for metal components with complex geometries such as free-form surfaces, deep grooves, and three-dimensional cooling channels. Our systems are designed to reduce your lead times without sacrificing strength and performance.

Larger Component Printing

More Parts Per Build

Advanced Material Options

Quality Finishing Options

DMLS Materials Comparison

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| Aluminum (AlSi10Mg) | Additive metal alloy known for its high Strength-to-Weight ratio for strong, light weight parts and corrosion resistant | Aerospace, automotive and industrial manufacturing application and complex geometries with intricate features | Machining for smooth, precise finishes; anodizin, powder coating | Spec Sheet |

| Cobalt Chrome | High-strength, wear-resistant alloy It has excellent corrosion resistance, biocompatibility, and can be easily welded or brazed | Aerospace, medical, and dental applications | Sandblasting, polishing, electroplating | Spec Sheet |

This a sampling of DMLS materials we work with. See more information on available materials and specs here.

Why Customers Choose UPTIVE

Latest Insights

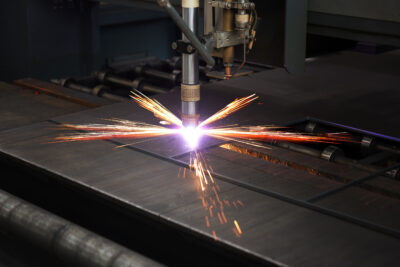

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

Composite Materials in Additive Manufacturing