How Rapid Prototyping Works

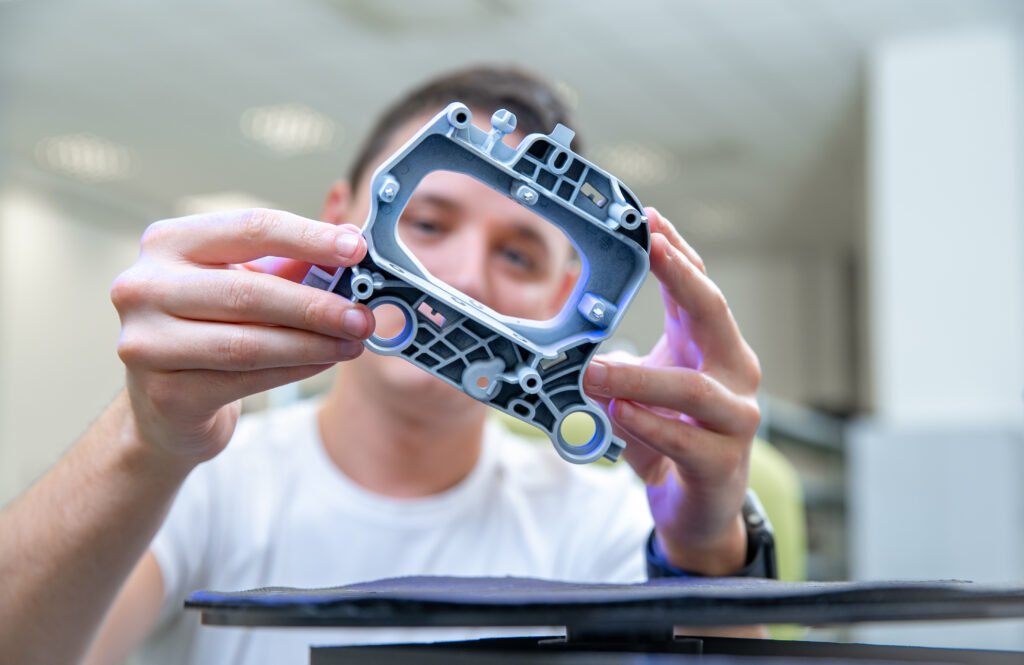

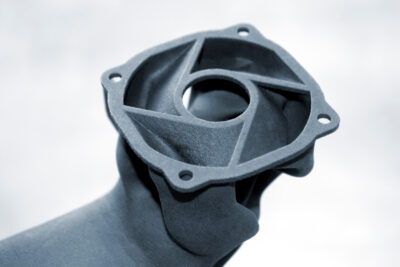

Rapid prototyping success can make or break new product development. We use a combination of quick-turn traditional and additive manufacturing processes to produce functional prototypes directly from a three-dimensional CAD file. Capable of achieving complex and precise part features, rapid prototypes are a critical step to prove out your concept and ensure part design, materials, and methods are dialed in before volume production begins.

Here’s how our rapid prototyping solutions can help you:

- Iterate multiple prototypes between digital designs and physical prototypes.

- Produce fully-functional prototypes and production-quality parts in a short amount of time.

- Quickly explore concepts and get them to market faster without sacrificing quality or consistency.

- Reduce (or in some cases, remove) tooling requirements by using the same equipment for prototyping and production.

Our Rapid Prototyping Capabilities

With our next-level material matching capabilities, we can guide you to ensure your prototype is made from the most suitable materials for your application and production requirements. We can also achieve multiple prototype iterations to help streamline the development process.

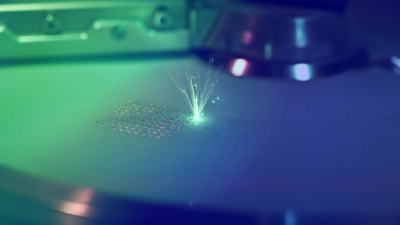

Direct Metal Laser Sintering (DMLS)

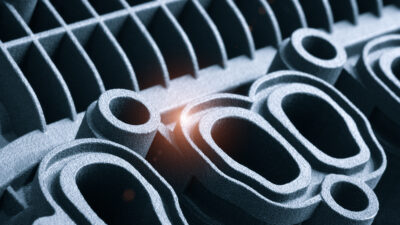

Selective Laser Sintering (SLS)

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

HP Multi Jet Fusion (MJF)

Polyjet (PJP)

CNC Prototyping

Sheet Metal Prototyping

Rapid Prototyping Processes Comparison

| Process | Description | Ideal For |

|---|---|---|

| 3D Printing/Additive Manufacturing | Builds physical objects layer by layer from a digital design, allowing for quick and precise prototyping of complex geometries | Prototypes with complex geometries, customized designs, and intricate details across various industries, including aerospace, automotive, medical, and consumer goods |

| CNC Machining | Uses automated tools to remove material from a block or sheet, allowing for precise and accurate prototyping of parts from various materials | Functional prototypes, low-volume production parts, and components that require high precision and accuracy in industries such as automotive, aerospace, electronics, and engineering |

| Rapid Injection Molding | Uses soft molds and thermoplastic materials to quickly produce small quantities of injection-molded parts, allowing for functional prototypes and low-volume production | Prototyping parts with thermoplastic materials, testing functionality, and producing low-volume production runs for consumer products, electronics, and automotive components |

| Sheet Metal Prototyping | Sheet metal fabrication techniques, such as laser cutting, bending, and welding, enable rapid prototyping of metal components with precise dimensions and geometries | Quick production prototypes of sheet metal components used in industries such as automotive, appliances, electronics, and enclosures |

| Rapid Tooling | Utilizing techniques like 3D printing or CNC machining, rapid tooling allows for the quick production of molds or tooling inserts, enabling faster iteration and production of parts | Quick production of molds or tooling inserts for injection molding, die-casting, or other manufacturing processes, enabling faster iterations and production of parts in various industries |

| SLA/DLP Resin Casting | Stereolithography (SLA) or Digital Light Processing (DLP) 3D printing technologies can be used to create master patterns, which are then used for resin casting to produce multiple copies of prototypes | Small-scale prototypes or low-volume production runs with high-quality surface finish and intricate details in industries such as jewelry, art, and consumer goods |

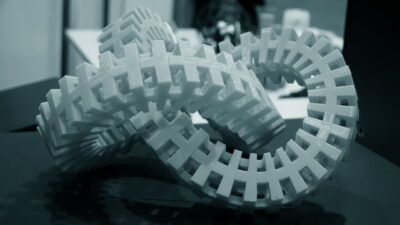

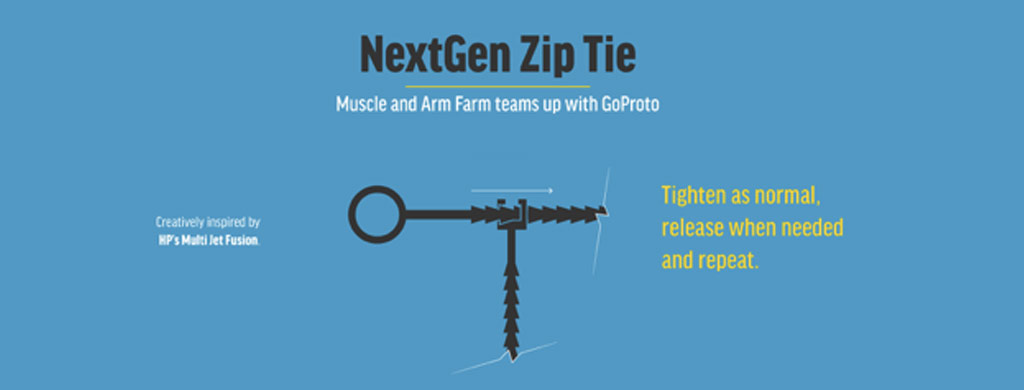

NextGen Zip Tie Case Study

With the help of their new HP Jet Fusion 3D 4200 Printer, UPTIVE was able to produce their client’s product at a level of quality that was comparable to what could be mass manufactured. The part was both strong and flexible. Download this case study to learn more.

Why Customers Choose UPTIVE

Latest Insights

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

Cost-Benefit Analysis of Rapid Prototyping: Maximizing ROI

Top 5 Trends in Traditional Manufacturing for 2024