How Sheet Metal Fabrication Works

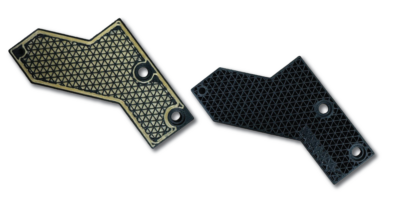

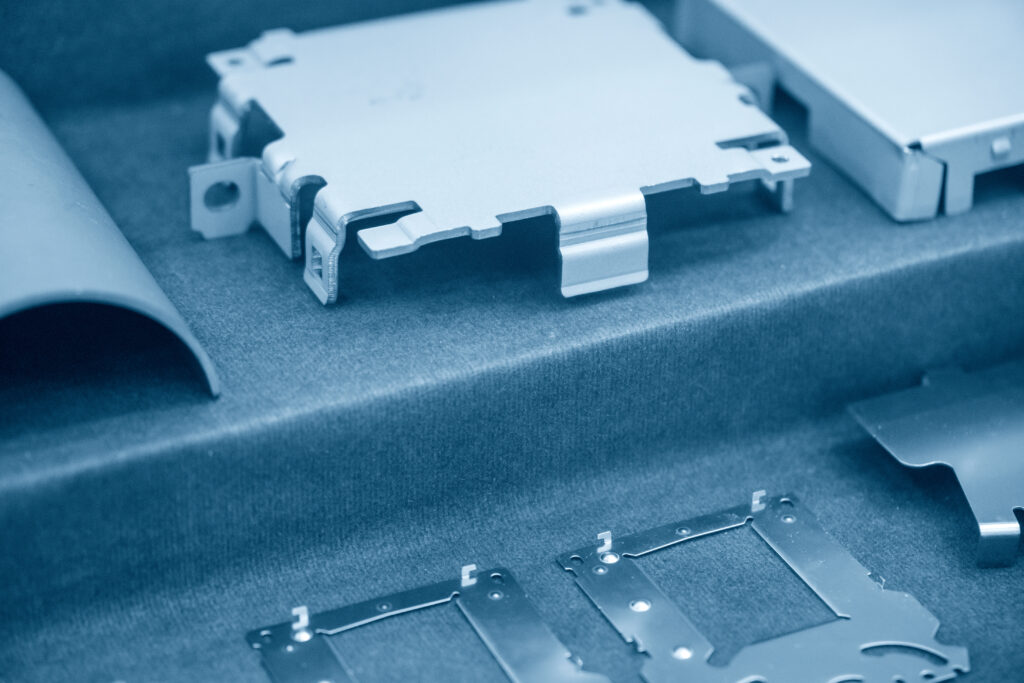

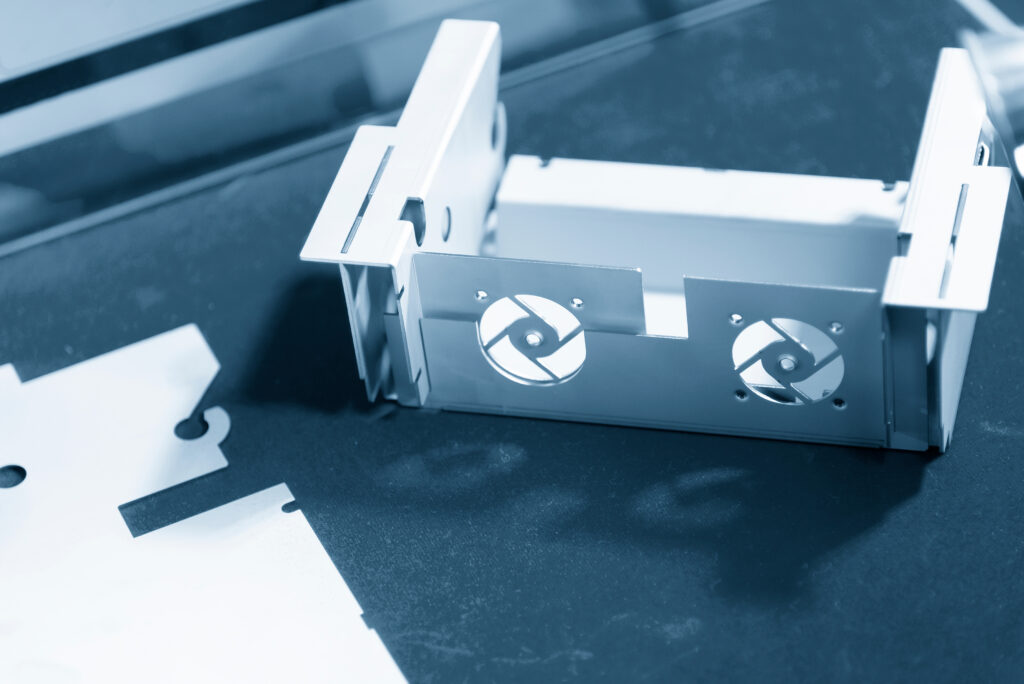

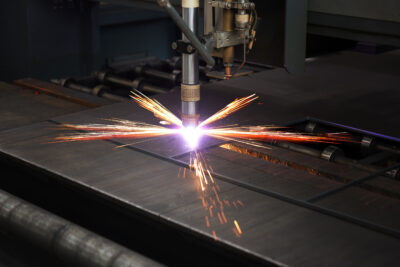

Sheet metal fabrication is a subtractive manufacturing process that creates parts from thin metal sheets. Our collaborative approach combines manual and automated processes to turn sheet stock materials into cuts, bends, and formed parts or assemblies, directly from your CAD file. Materials include aluminum, stainless steel, cold-rolled steel and beryllium copper. Each metal or alloy is selected based on mechanical properties, aesthetics, and performance characteristics based on part or component specifications.

Here’s how our sheet metal fabrication solutions can help you:

Choose materials for desired properties: aesthetics, corrosion resistance, higher strength-to-weight ratio, etc.

Remove the need for tooling with more automated prototype-to-production sheet metal fabrication solutions.

Save production costs by eliminating potential design errors that can negatively impact part maneuverability.

Increase accuracy for rapid prototypes in quantities as low as one, or for higher-volume production.

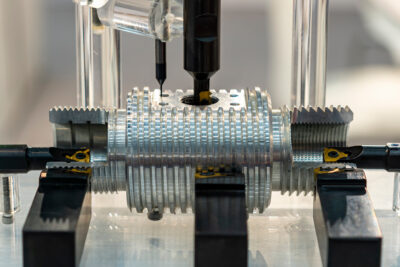

Our Sheet Metal Fabrication Capabilities

At UPTIVE, we can match the right sheet metal fabrication process with the most appropriate material in order to reduce your production lead times and reduce overall costs. The below capabilities are just a few examples of how we’re bridging the gap between how sheet metal parts are designed in CAD and how they are actually fabricated on the shop floor. Our consultative approach is designed to get you your parts on time and within specification.

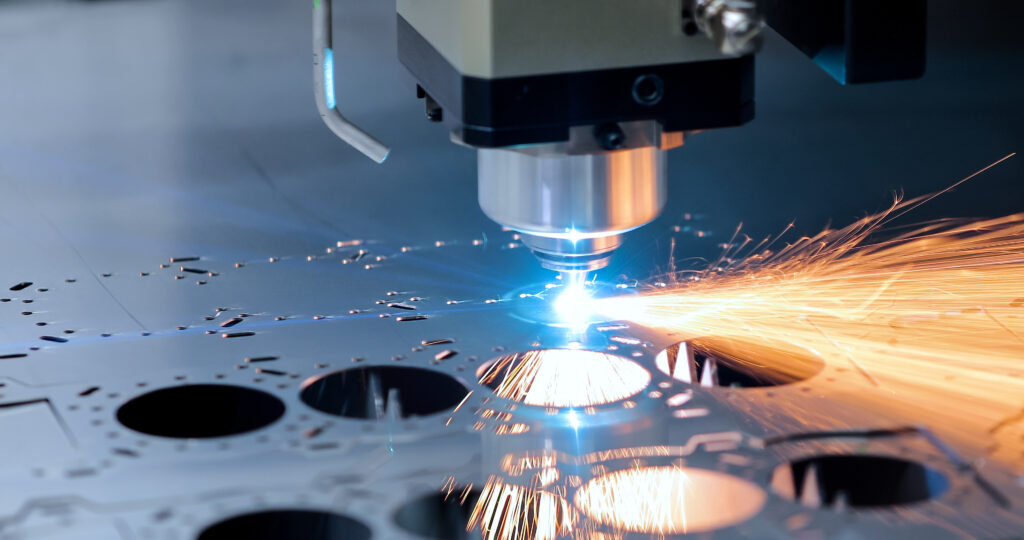

Cutting

Stamping

Welding

Value-Add Hardware

Finishing

Sheet Metal Fabrication Processes Comparison

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| Aluminum | Lightweight and corrosion-resistant metal | Aircraft parts and building facades | Anodizing, painting, or powder coating for corrosion resistance and decorative purposes | Spec Sheet |

| Beryllium Copper | High-strength, non-magnetic alloy that contains beryllium and copper | Aerospace components and electronic connectors | Polished or textured to achieve a specific surface finish, or plated with other metals for improved corrosion resistance and aesthetics | Spec Sheet |

| Cold-Rolled Steel | Steel that has been rolled at room temperature to increase its strength and smoothness | Machinery components and construction materials | Plating or painting, for corrosion resistance and improved aesthetics | Spec Sheet |

| Pre-Plated Cold-Rolled Steel | Cold-rolled steel that has been pre-coated with a layer of metal, such as zinc or tin, for corrosion resistance | Appliance panels and automotive parts | Paint or powder coat, for additional corrosion resistance and decorative appearance | Spec Sheet |

| Stainless Steel | Corrosion-resistant steel that contains chromium | Food processing equipment and medical devices | Polishing or bead blasting, for a smooth and attractive appearance, or passivation to increase corrosion resistance | Spec Sheet |

This is a sampling of sheet metal materials we work with. See more information on available materials and specs here.

Sheet Metal Fabrication Design Guide

Download this best practice guide to help bridge the gap between design and fabrication with precision parts, weldments, and assemblies, at the quickest lead times possible.

Why Customers Choose UPTIVE

Latest Insights

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

Composite Materials in Additive Manufacturing