Welcome to the cutting-edge world of additive manufacturing, where innovation meets ingenuity. At UPTIVE Manufacturing, we’re dedicated to unlocking the full potential of advanced materials, and today, we’re shining the spotlight on composite materials.

Let’s explore what composite materials are, their properties, potential applications, and which industries they can be used in.

What are Composite Materials in Additive Manufacturing?

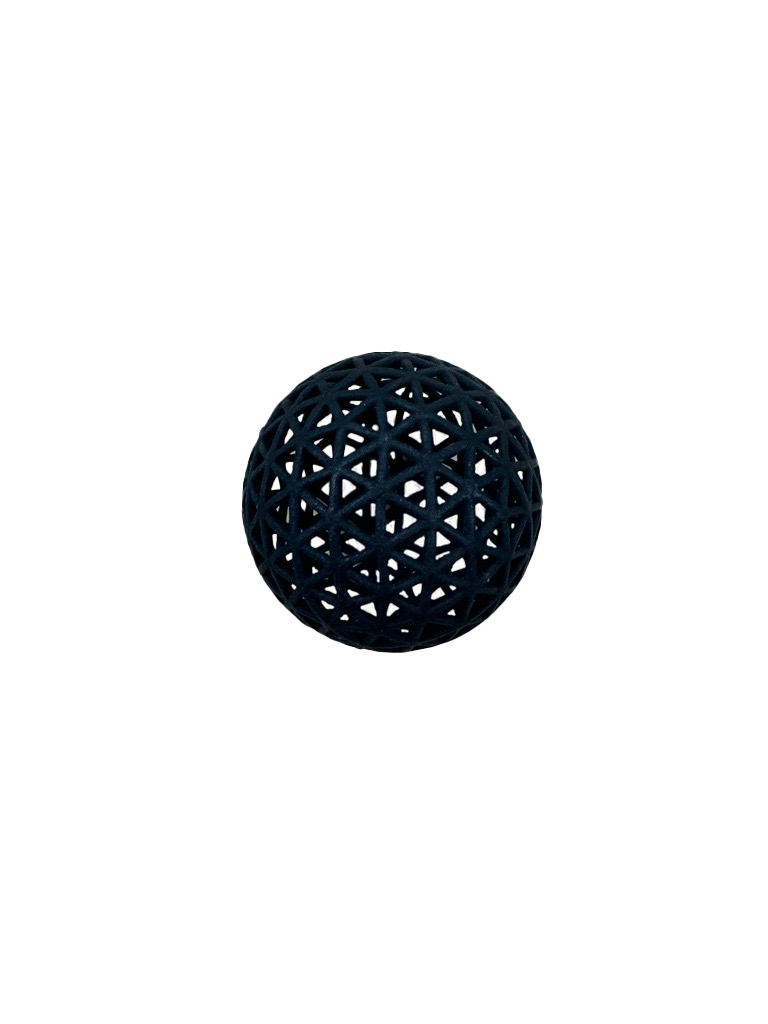

Composite materials are engineered substances crafted by two or more distinct materials that have different chemical and physical properties to create a product with enhanced properties.

These materials typically consist of a matrix, which serves as a base, reinforced with fibers or particles. The blend of these components results in a material that surpasses the performance of non-composite materials.

Properties of Composite Materials in Additive Manufacturing

The properties of composites can be broken into two different categories; chemical and physical properties.

The overall properties of composite materials include;

- Strength and durability

- Lightweight

- Flexibility and customization

- Corrosion resistance

What are the chemical properties of composite materials in additive manufacturing?

- Chemical composition: Chemical properties refer to how a material interacts with other substances on a molecular level. In composite materials, the chemical properties are primarily determined by the constituents of the matrix and reinforcement materials. For instance, if the matrix material is a thermosetting resin like epoxy, it will exhibit different chemical properties compared to a thermoplastic matrix like polyamide.

- Chemical stability: The chemical stability of a composite material influences its resistance to degradation when exposed to various environmental factors such as moisture, chemicals, and temperature extremes. Certain composite materials are engineered to have excellent chemical stability, making them suitable for applications in corrosive environments or chemical processing industries.

- Chemical reactivity: Some composite materials may undergo chemical reactions under specific conditions. For example, composite materials containing metallic reinforcements may react with certain chemicals or environments, leading to corrosion or degradation over time. Understanding the chemical reactivity of composite materials is essential for predicting their long-term performance and durability.

What are the physical properties of composite materials in additive manufacturing?

- Mechanical strength: Physical properties encompass a wide range of characteristics related to the material’s mechanical behavior. This includes properties such as tensile strength, compressive strength, flexural strength, and modulus of elasticity. Composite materials are renowned for their exceptional mechanical properties, often exhibiting higher strength-to-weight ratios compared to traditional materials like metals or plastic.

- Density and weight: Density and weight are crucial considerations, especially in weight-sensitive applications such as aerospace and automotive industries. Composite materials are prized for their low density and lightweight nature, contributing to fuel efficiency and overall performance improvements.

- Thermal conductivity and insulation: Thermal properties play a significant role in determining how composite materials respond to changes in temperature. Some composites exhibit high thermal conductivity, making them suitable for applications requiring efficient heat transfer, while others offer excellent thermal insulation properties, ideal for applications where temperature control is critical.

- Electrical conductivity: Depending on the composition and arrangement of the reinforcement materials, composite materials may exhibit varying degrees of electrical conductivity. This property is essential in applications such as electronics, where materials with specific electrical properties are required to ensure optimal performance and reliability.

Different Uses for Composite Materials in Additive Manufacturing

Aerospace: Composite materials have revolutionized the aerospace industry, offering lightweight yet durable components for aircraft, spacecraft, and satellites. From fuselages to wing structures, composites play a crucial role in enhancing fuel efficiency and performance.

Automotive: In the automotive sector, composite materials are transforming vehicle design and manufacturing. From carbon fiber-reinforced polymers (CFRP) to fiberglass composites, these materials contribute to weight reduction, improved fuel economy, and enhanced safety.

Medical: In the medical field, composite materials find applications in prosthetics, orthopedic implants, and medical devices. The biocompatibility and customizable properties of composites make them invaluable for creating patient-specific solutions.

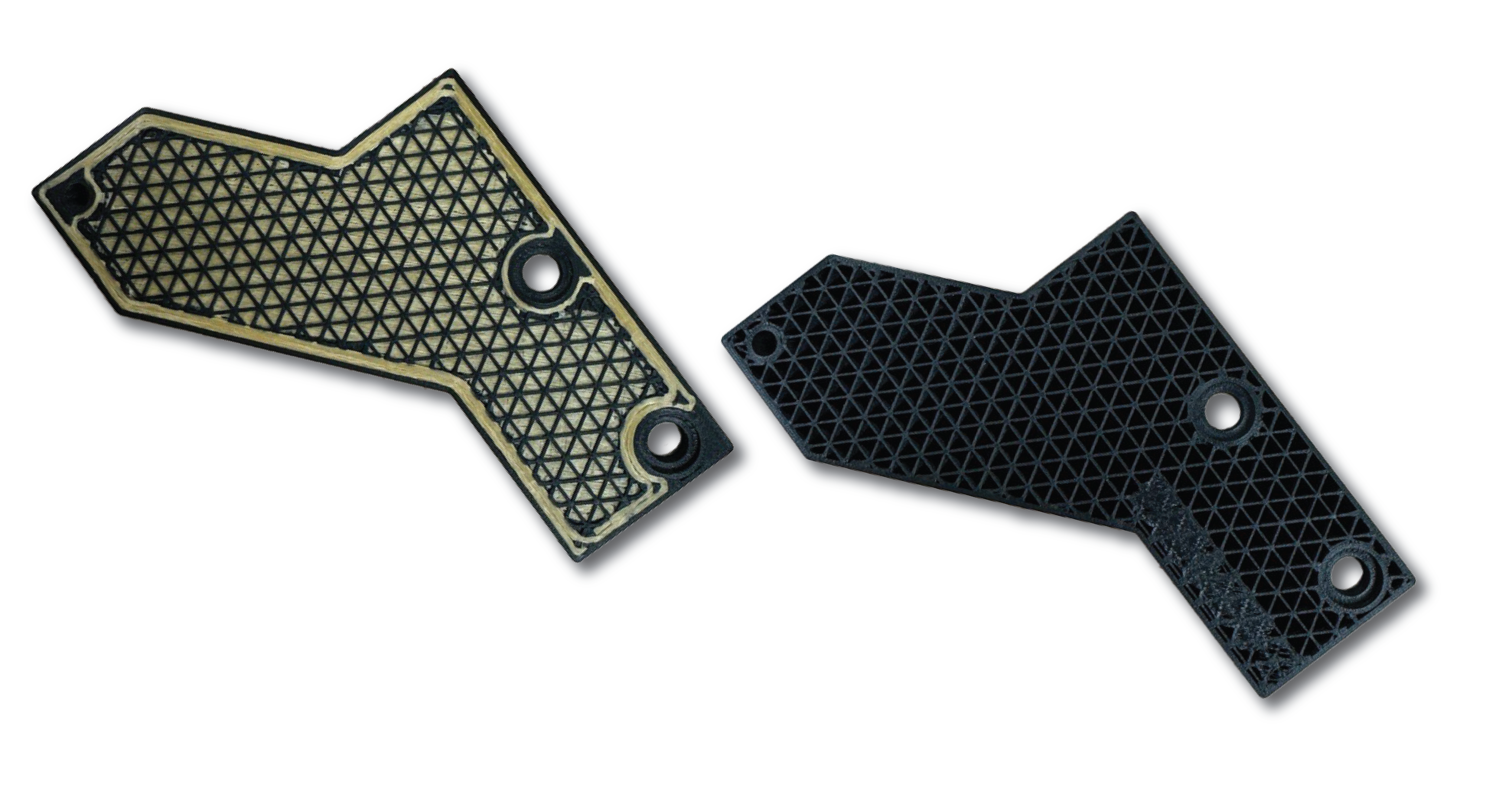

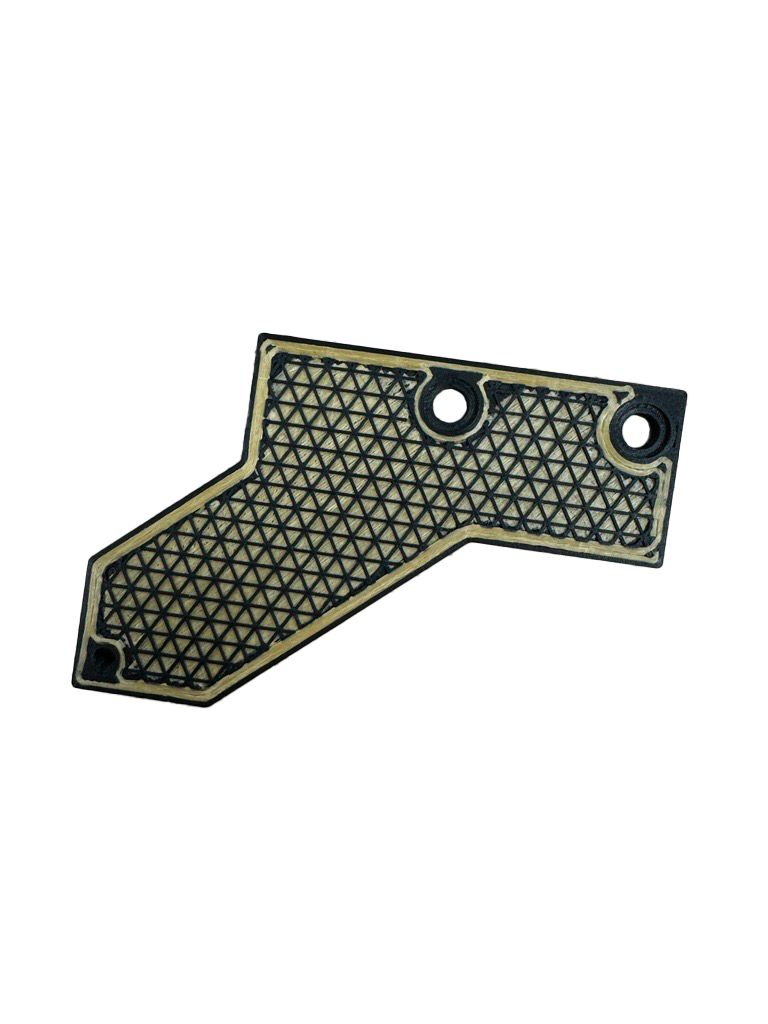

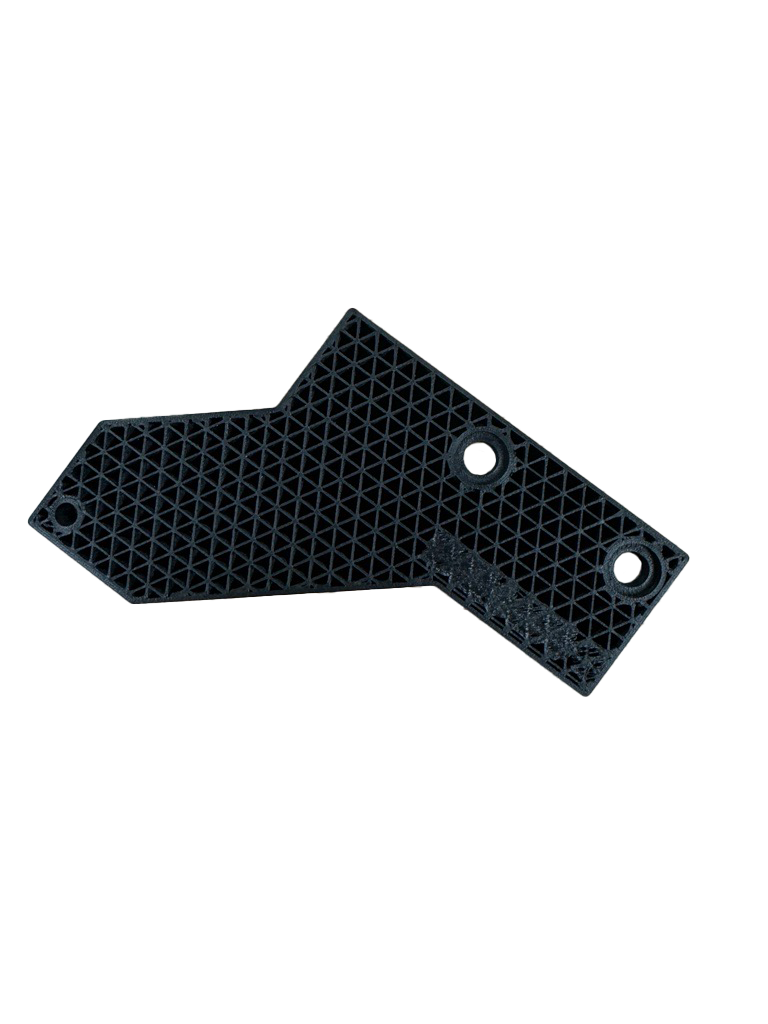

Composite Materials at UPTIVE Manufacturing

| MATERIAL | PROCESSES | DESCRIPTION | IDEAL FOR | SPEC SHEET |

| Nylon-12 Chopped Carbon-Filled | Fused deposition modeling (FDM) | Nylon material reinforced with chopped carbon fiber for improved stiffness and strength | Gears, bearing, and other components | Here |

| Onyx | Markforged | Carbon fiber-filled nylon material that is strong and stiff, with good dimensional stability and heat resistance | Tooling fixtures, jigs, and other components | Here |

| Onyx FR | Markforged | A flame-retardant version of Onyx that is suitable for applications where fire safety is a concern | Electrical enclosures, automotive components, and other applications | Here |

| PA-12 Glass Bead | HP Multi Jet Fusion, Fused deposition modeling (FDM), Selective laser sintering (SLS) | Glass-bead-filled nylon PA-12 material that has improved stiffness and dimensional stability | Gears, bearings, and other components | Here |

Summary

Composite materials represent a paradigm shift in additive manufacturing, offering unmatched versatility, strength, and customization. At UPTIVE Manufacturing, we’re at the forefront of composite prototyping, empowering businesses across diverse industries to realize their boldest ideas.

Explore the endless possibilities of composite materials with UPTIVE Manufacturing.