Sheet metal fabrication is a multifaceted manufacturing process that involves the shaping, cutting, and assembling of metal sheets to create a wide range of custom components. This process is essential for numerous industries, including automotive, aerospace, and electronics, and is known for its versatility and precision.

In this blog article, we will explore the intricacies of sheet metal fabrication, its key benefits, and how it is applied across various industries.

Understanding Sheet Metal Fabrication

Sheet metal fabrication encompasses a variety of processes that work in tandem to transform flat metal sheets into complex structures. These processes include cutting, bending, welding, and finishing. Each stage requires specialized equipment and skilled operators to achieve the desired results.

1. Cutting

The first step in sheet metal fabrication is cutting, which involves slicing metal sheets into specified shapes. This can be done using different methods such as:

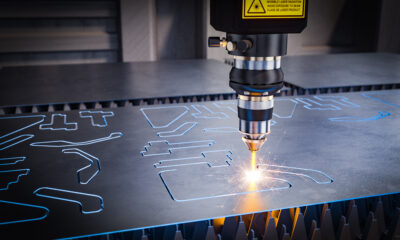

- Laser Cutting: A high-precision method that uses a focused laser beam to cut intricate patterns and designs in metal sheets.

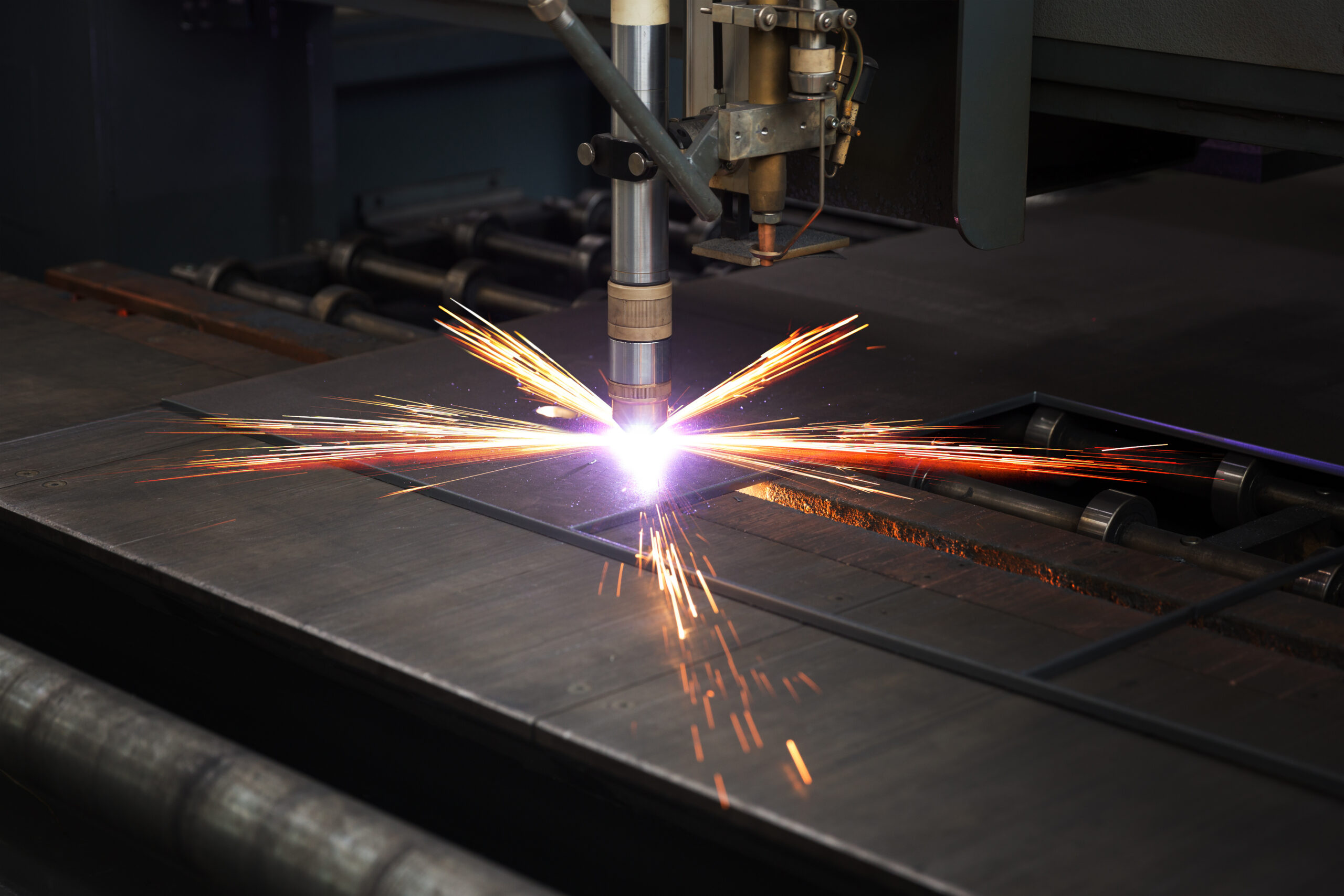

- Plasma Cutting: A process that uses a high-velocity jet of ionized gas to cut through sheet metal.

- Water Jet Cutting: A process that employs high-pressure water mixed with abrasive materials to cut through metal sheets with ease.

- Shearing: A method that uses a machine with blades to cut straight lines in metal sheets.

2. Bending

After cutting, the next step is bending the metal sheets into the desired shapes. This is typically done using press brakes, which apply controlled force to bend the metal accurately and consistently. This process allows for the creation of complex angles and shapes.

3. Punching

Punching is a process used to create holes, slots, or other shapes in metal sheets. It involves pressing a punch through the metal to achieve the desired shape. This method is precise and efficient, making it ideal for creating consistent patterns in the metal.

4. Welding

Welding is a crucial process in sheet metal fabrication as it joins metal pieces together to form complete structures. Different welding techniques, such as MIG, TIG, and spot welding, may be used depending on the material and application.

5. Finishing

The final step in sheet metal fabrication is finishing. This process enhances the appearance and durability of the fabricated metal parts. Finishes that UPTIVE offers include:

- Powder coating

- Buff polishing

- Sand blasting

- Brushing plating

The Benefits of Sheet Metal Fabrication

Sheet metal fabrication offers several key advantages for manufacturers and industries:

- Precision and Accuracy: Modern sheet metal fabrication techniques enable the creation of intricate and precise metal components that adhere to exact specifications.

- Versatility: Sheet metal fabrication works with various types of metals, including steel, aluminum, and stainless steel. This allows manufacturers to cater to diverse project requirements.

- Cost-Effectiveness: Using materials and processes efficiently in sheet metal fabrication reduces waste and saves money for manufacturers.

- Durability: Fabricated metal parts are known for their strength and resilience, making them ideal for applications that demand durable and reliable components.

Applications of Sheet Metal Fabrication

Sheet metal fabrication plays a pivotal role in a wide array of industries:

- Automotive: In the automotive industry, sheet metal fabrication is used to produce body panels, frames, and other structural components.

- Aerospace: The aerospace industry relies on sheet metal fabrication to create precision metal parts for aircraft and spacecraft.

- Electronics: Sheet metal is utilized in the production of electronic enclosures, cases, and other components.

Summary

Sheet metal fabrication is a vital process that underpins many industries, providing the foundation for creating complex and precise metal components. From cutting and bending to welding and finishing, each stage of sheet metal fabrication requires skill and precision.

Whether you are in the automotive, aerospace, construction, or electronics industry, understanding what sheet metal fabrication is and how it can benefit your projects is key to achieving your manufacturing goals. So, the next time you think about custom metal parts, remember the vital role that sheet metal fabrication plays in bringing your designs to life.