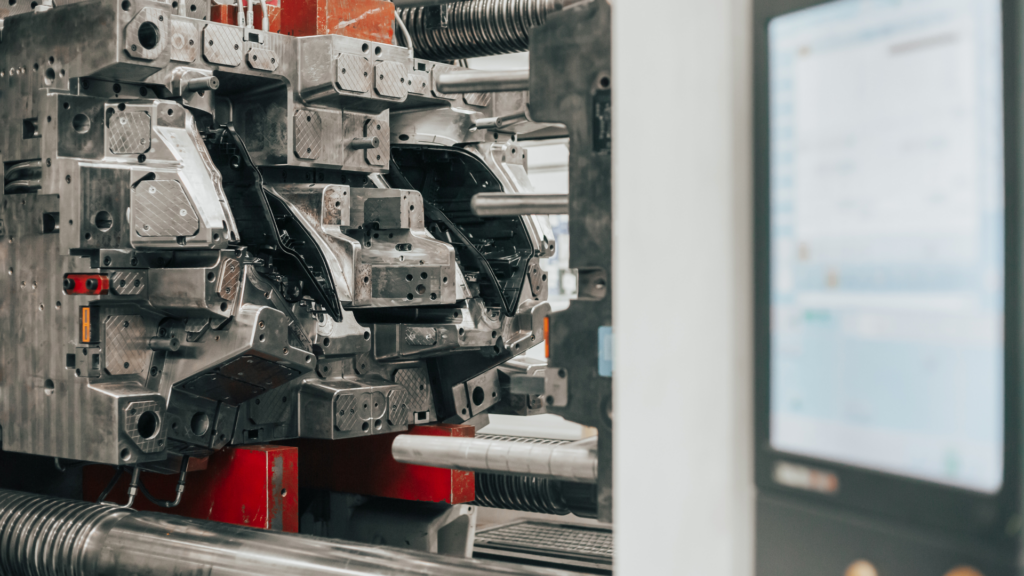

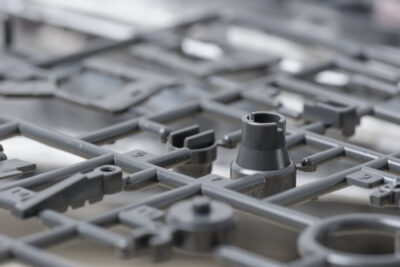

How Injection Molding Works

Prototype injection molding is the process of injecting molten plastic into a permanent aluminum or steel tool to form molded plastic parts. UPTIVE works with you to educate and determine which of the latest injection molding technologies, materials, and processes are necessary to create world-class parts that match your exact specifications. Our team of experts and precision tooling capabilities enable us to fabricate intricate molds in quick turnaround times with optimal results using a wide array of plastic, elastomeric, and filled materials to produce quality, durable parts, even in higher volumes.

Here’s how our plastic injection molding solutions can help you:

- Increase throughput for medium to high-volume production runs (10,000 to 100,000 parts).

- Produce parts with superior structural integrity & durability for end-use products.

- Achieve comprehensive customization and detail in geometry, texture, and more.

- Minimize material waste with any excess often able to be recycled for future use.

- Reduce cost per part using UPTIVE proprietary aluminum molds instead of steel.

Our Injection Molding Capabilities

Our injection molding systems are designed to deliver extremely quick-turn parts while achieving the precision and speed you require.

Consultative Approach

Manufacturing Versatility

Extensive Materials

Quick Turn

Custom Tooling

Injection Molding Materials Comparison

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| ABS | Thermoplastic material that is known for its high impact strength, toughness, and affordability | Automotive trim, housings, and consumer goods | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| ACRYLIC | Transparent thermoplastic material that is known for its optical clarity, UV resistance, and scratch resistance | Lighting fixtures, displays, and lenses | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| ELASTOMER/RUBBER | Flexible and elastic material that is used to create parts such as seals, gaskets, and other components that require flexibility and compression | Seals, gaskets, and other components that require flexibility and compression, such as in automotive, medical, and consumer goods applications | Painting or powder coating, to improve their appearance and durability | Spec Sheet |

| GLASS-FILLED PC, ABS, NYLON | Reinforced thermoplastic materials that are made by blending glass fibers with the base material, increasing their strength, stiffness, and heat resistance | Automotive and aerospace components, electronic housings, and industrial equipment | Painting or powder coating, to improve their appearance and durability | Spec Sheet |

| NYLON | Versatile engineering thermoplastic material that is known for its high strength, toughness, and durability | Gears, bearings, and structural components in automotive, aerospace, and industrial applications | Painting or powder coating, to improve their appearance and durability | Spec Sheet |

| PC | High-performance engineering thermoplastic material that is known for its excellent impact strength, heat resistance, and transparency | Automotive and aerospace components, electronic housings, and medical equipment | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| PC+ABS | Blend of PC and ABS materials that combines the toughness of ABS with the heat resistance of PC | Automotive interiors, electronic housings, and appliances | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| TPO | Thermoplastic material that is known for its excellent impact strength, weather resistance, and affordability | Automotive components such as bumpers, fenders, and door panels | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| ULTEM 1000 | High-performance engineering thermoplastic material that is known for its excellent heat resistance, strength, and stiffness | High-performance parts such as aerospace components, electrical insulators, and medical equipment | Polishing or texturing, for a smooth and attractive appearance, or post-processed with coatings to improve their resistance to heat and chemical exposure | Spec Sheet |

| ULTEM 2300 | High-performance engineering thermoplastic material that is known for its excellent heat resistance, strength, and stiffness, with added flame retardant properties | High-performance parts such as electrical components and structural parts in aircraft and trains | Polishing or texturing, for a smooth and attractive appearance, or post-processed with coatings to improve their resistance to heat and chemical exposure | Spec Sheet |

This is a sampling of injection molding materials we work with. See more information on available materials and specs here.

Why Customers Choose UPTIVE

Latest Insights

Plastic CNC Machining

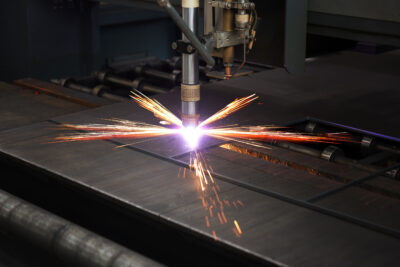

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing